The new belt drive for the MDDK/L roller mill offers substantial advantages over the gear drive version.

This power transmission is easy to install and makes maintenance very much easier and more cost efficient.

Buhler scope of supply:

The retrofit kit is supplied complete with all the components required for installation, including conversion instructions. The assembly kit includes 1 spare belt. For the conversion, one installation set is required per plant. The price does not include installation. Time requirement for conversion is two to three hours per roll pair.

Your benefits

- Easy conversion

- High power

- No gear oil and therefore excellent sanitation

- Easy maintenance

- Simplified roll changes

- Snub wheel with for-life-lubricated bearings

- No different gearwheels required for rolls with

- reduced diameter

- Only one belt type for all transmission ratios

Why upgrade?

-

Run quieter – Say goodbye to gearbox clatter

-

Maintain less – No more oil leaks or gear wear

-

Adjust easier – Simple belt tension control

-

Install fast – Our kit fits perfectly, no guesswork needed

Made for your mill:

-

Direct replacement – Perfectly replaces the original gear drive system

-

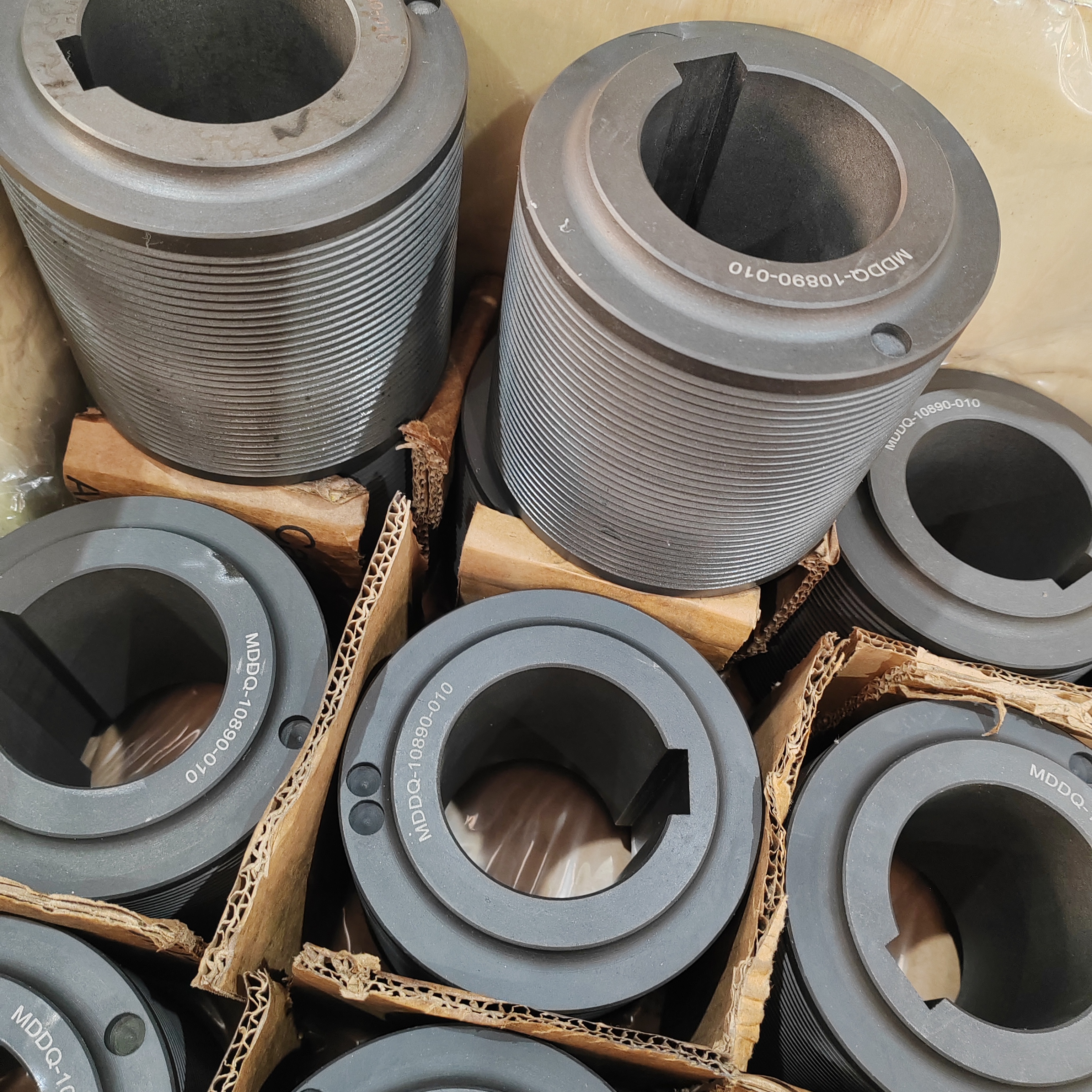

Precision manufactured – CNC-machined pulleys with premium timing belts

-

Complete package – Includes all mounting hardware and instructions

-

Precise fit – Designed specifically for MDDK & MDDL models

CAUTION: Applies to MDDK/L

The roll speed must be checked for the correct torque and if necessary be modified at the drive end. Graphic 1 shows the minimum speed, which must always be reached. If the roll motor power is known, it will be possible to derive the speed. If the speed is too low, this will reduce the belt service life.

Ready to make the switch?

Send us your mill model number → We'll match the right kit → Get it running in days, not weeks.

Limited kits in stock.

.jpg)